Automation can be found nearly everywhere we go because of all the comfort, convenience, safety, and operational efficiency it offers to society. With all the benefits automation has to offer, many have decided to make use of this technology in their homemade projects. If you needed some actuator DIY project ideas before going out to buy a linear actuator for a project, you’ve came to the right place! This article will cover our customer's top 5 homemade automation projects you may find some inspiration from. We will go over the details and products used in each application to gain a better understanding on what it takes to make projects like these come to life.

Browse our full range of electric linear actuators to create your own project!

DIY Linear Actuator Projects

The Top 5 linear actuator projects we cover will show the versatility automation offers for many different applications that are useful in people’s daily lives. These 5 customer projects are also going to be homemade to show anyone can build one.

Our Top 5 most interesting homemade projects using automation:

- Executive Stand Up Desk DIY

- DIY Chicken Coop Automatic Door Opener

- Automated Fire Grill

- Tiny House Bed Lift with Linear Actuators

- Automated Secret Bookcase Doors

1. Executive Stand Up Desk DIY

Electric standing desk technology is becoming very popular for reducing bad posture and to promote a more active work style. The Executive Stand Up Desk by Joshua Mouch is a great project to refer to if you are looking for ideas to create your very own DIY desk using linear actuators! Pre-built standing desks have the convenience of high availability, however, making your own DIY desk using linear actuators allows for more user options to personalize the style, color, shape, and size.

Check out Joshua’s video of the Executive Stand Up Desk in action:

This custom desk makes use of our FLT-04 as the legs for lift and support. The FLT-04 is our only lifting column that comes with 4 legs to ensure high weight capacity and the most surface area of contact during the mounting stage. It also has the convenience of coming as a set with the compatible control box and remote included. With synchronized actuators built into the FLT-04 legs, Joshua can adjust the height of his custom desk without any concern of the work surface tilting or being uneven while still operating at a low noise level and good speed.

Now we have introduced our modular lifting columns, 4x LG-02 lifting columns, 1x FLTCON-4 control box, and 1x RT-11 remote works just the same as the FLT-04! Our modular lifting columns are single-unit legs of a lifting column that can be paired with our remotes and FLTCON series of control boxes that can handle between 1 to 4 legs in a single control system. Select from our large range of remote options and enjoy all the unique features of our different programmable wired remotes that can be used together with wireless remotes for extra convenience.

For more information on the detailed project build, we have included a link to our instructables as reference:

https://www.instructables.com/Converting-an-Executive-Desk-Into-a-Standing-Desk/

Home automation is becoming more popular, including TV lifts and electric standing desks!

2. DIY Chicken Coop Automatic Door Opener

When taking care of chickens, some of the responsibilities include ensuring they have access to water, sunlight and ventilation. Shutting the chickens in and letting them out of their coop everyday normally requires manual labor, however, Mike Senna’s DIY Automatic Chicken Coop Door makes this duty easier and convenient with the use of automation.

Mike required a water protected solution for his 12v actuator project since chicken coops are exposed to outdoor environments. Opening and closing the chicken coop’s door did not require much force so an actuator with high force ratings was not mandatory. The PA-06-6-180 actuator was selected for its IP67M rating to ensure water protection even while moving. He was also able to integrate Google’s home automation software with our actuator to open and close the door from anywhere in the world!

Check out our “DIY Automatic Chicken Coop Door” video to see this project physically in action and more visual references on the assembly:

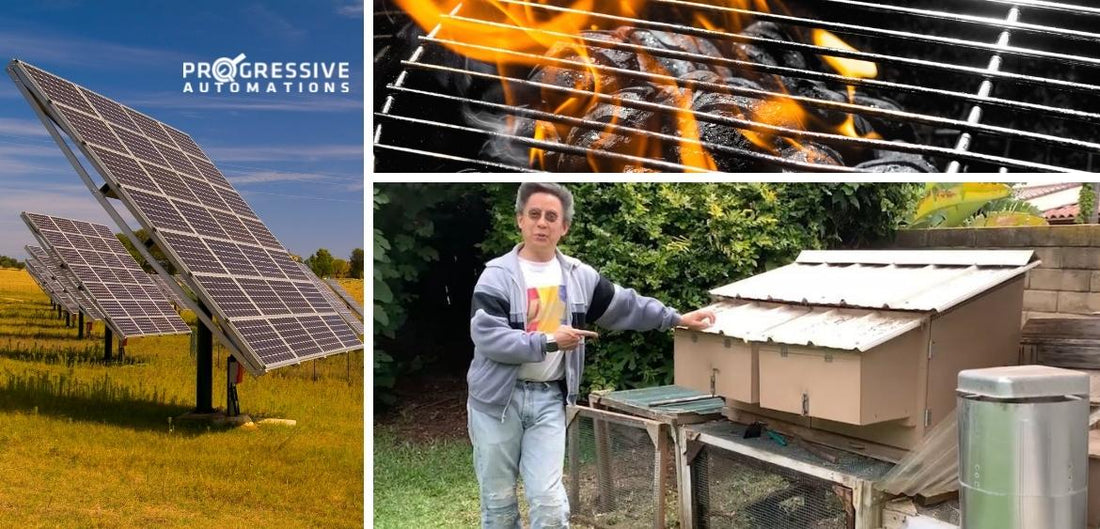

3. Automated Fire Grill

Fire pit grills are fantastic during the summer for making great tasting BBQ foods. By integrating an electric actuator, our customer John McGurk was able to raise and lower his automated burger grill rack while holding a spatula (or beer!) in one hand. This project makes the task of cooking and managing a grill easier while socializing at the same time.

Due to the aluminum tubes constructed for the grill, John needed an actuator that was compact enough to meet the space restrictions. He selected our PA-15 High Speed Linear Actuator as its tubular shape was the right fit. The PA-15 also runs at a high speed of 3.2 inch/second with no load for the 33 lbs force model, allowing for fast grill operation to avoid overcooked foods. This model’s ingress protection rating of IP54 was also more than sufficient for John’s project.

For a more detailed look into the automated fire grill, we have included a link to the project’s article below:

Automated Fire Grill (Video/GIF)

4. Tiny House Bed Lift with Linear Actuators

Space efficiency is always a nice bonus for any project; however, it becomes much more crucial for settings like in a tiny house. By using a Tiny House Bed Lift with Linear Actuators, innovative customers like Sam can maximize their available space without compromising in comfort or convenience.

Check out the “Automated Bed Lift in a Tiny House” video to see the lift in action:

Sam chose the PA-04-HS actuators as they have sufficient force ratings of 400 lbs per actuator and are the only off the shelf actuators with built-in Hall effect sensors. When connected with the FLTCON-4 control box and RT-11 remote, Hall effect feedback allow the actuators to move synchronously even with uneven weight distribution on the bed. The use of guide rails also ensured there was a pre-defined path of travel for their DIY linear motion systems.

We have included the full article below for a more in-depth overview of the steps required to build your very own bed lift mechanism:

5. Automated Secret Bookcase Doors

A manual secret door that’s well disguised can be an effective way of keeping your treasured belongings safe or to have your own secret lair. Forgetting to close the secret door or just leaving it open for convenience happens far too often, however, the use of Automated Secret Bookcase Doors ensures they can close automatically when needed.

Check out the DIY Automated Secret Bookcase Doors in action:

This linear actuator project by Bruce McArdle required a solution that was able to open and close within an acceptable timespan while not being too fast as this can shake the contents in the bookcase. The actuators Bruce selected were the PA-14-8-50 because they had the right amount of force and were just fast enough with a speed of 0.83 inch/second fully loaded. Since the bookcase is indoors, the IP54 rating of each actuator was more than sufficient. By programming an Arduino microcontroller, the actuators can activate to close the doors if there was no motion detected in the room after 2 hours.

For more information on the detailed project build, we have included a link to the instructables and article as reference:

https://www.progressiveautomations.com/blogs/stories/automated-secret-bookcase-doors-project

https://www.instructables.com/Electro-Mechanical-Control-of-Hidden-Bookcase-Door/

Pairing your actuator with a compatible control system is key - browse our range!

Portable Solar Tracker (Bonus Project)

Although not made by a customer, our team’s Portable Solar Tracker is an extra homemade project we want to feature since clean and renewable energy is very useful for everyone. The portability also ensures it can be used for a mobile lifestyle or at home to benefit from energy cost savings while also reducing our environmental footprint.

Using an actuator to follow the sun through a single axis of motion increases the solar panel’s power yield by up to 25% more than a stationary solar panel. In this project, the PA-14-6-150 actuator was chosen since it draws less current than the 35 lbs force version for the load being applied. Our PA-14 actuators also have the benefits of being small, light weight and portable.

Our “how to” article and video goes in-depth with visual references on the creation and assembly of the Portable Solar Tracker:

https://www.progressiveautomations.com/blogs/how-to/how-to-build-a-portable-solar-tracker

In summary

The use of automation technology can be found in many homemade projects like these to help improve our daily lives. Whether you were looking to improve comfort, convenience, safety, or operational efficiency, we are confident that you too can take your project to the next level!

We hope you found this article informative and helpful at giving some new ideas for your next build.

Thank you to all our customers for sharing your interesting projects!

If you need an actuator for your project or have any technical questions on our products, feel free to reach out to us. We look forward to hearing from you and will be happy to share your future custom projects!

sales@progressiveautomations.com

1-800-676-6123