Electric linear actuators are popular in marine OEM applications due to the significant improvement in operational convenience they can provide. Aside from their versatility of being available in many different sizes and specifications, electric actuators also offer key benefits that are not present in hydraulic and pneumatic alternatives. This article will cover the important aspects of boat actuators for marine OEMs to consider such as their use cases, cost-benefit analysis, and important specifications.

Use Cases

Common use of electric actuators for marine OEMs are found on a boat, yacht, and other sea vessel related applications. Electric actuators have been used for providing linear motion when changing the positions of:

- Engine hatches

- Windows

- Doors

- Storage compartments

- Boat sheds

- Furniture

- Thrusters

- Bimini tops

- Wakeboard racks/towers

- Boat lifts

Engine Hatches

One of our marine case studies shows an example of our customer’s success using the PA-04-HS as a marine engine hatch lift actuator. With Hall effect sensors to provide positional feedback, a control system monitors and calibrates the positions of each actuator to move synchronously. Our customer was then able to mount the actuators on each side of the engine hatch without obstructing the normal path into the engine compartment.

Boat Sheds

Custom PA-04 actuators raising a boat shed

Another use case of electric actuators is to raise and lower boat sheds. With the use of remote-controlled systems, users can control the position of their actuators for raising boat sheds when moving their boats. After returning the boats, an operator can remotely control their electric actuators and lower the boat sheds to help keep the boats clean and dry for future use. Once closed, the boat shed also ends up covering most of the actuator’s body which further increases the actuator’s lifespan by reducing water exposure.

Cost-Benefit Analysis

Actuators that are found in the industry are generally hydraulic, pneumatic, or electric.

-

Hydraulic actuators are generally the most expensive solution. They require bulky pumps and hoses, and are leak prone which can be detrimental to the safety of marine flora and fauna.

- Pneumatic actuators are also pricey and bulky. However, they would only leak air which would not affect the environment such as hydraulic actuators.

- Electric actuators are cheap, compact, and free of harmful chemicals. A great benefit is that they do not need maintenance, which in turn keeps operational costs lower.

While each marine electric linear actuator type has their strengths and weaknesses depending on the application, we will focus on the major benefits of electric actuators:

- Ease of use

- Low maintenance

- Eco-friendly operation

1. Ease of Use

A benefit of using electric linear actuators is the convenience they offer as a simple-to-operate alternative for producing linear motion. Standard electric actuators use a brushed DC motor and have a simple 2-wire operation to extend and retract. Wiring an actuator to a rocker switch or control box allows for a neat and tidy setup with no need for tubes, valves or hoses found in hydraulics and pneumatics seen below.

Pneumatic System Components

Although alternatives may have a lower up-front cost for producing linear motion, electric linear actuators eliminate the inconvenience of all the extra labor required for integrating them as fast drop in solutions.

2. Low Maintenance

Electric linear actuators are self lubricated internally for the life of the unit, and require no maintenance when used within their ratings. This helps in saving labor time and resources over the span of the electric actuator’s service life. There are also options with waterproof Ingress Protection and salt spray ratings for more corrosion resistance in the elements. As a result, they have an improved lifespan which reduces the need for frequent replacements.

Electric Actuator Internal Components

3. Eco-Friendly Operation

Alternatives like hydraulics and pneumatics require more working components to operate like heat exchangers, fluid reservoirs, regulators, and compressors. The extra materials and heat generated from more working components has a harder impact on the environment. Electric actuators ensure an environmentally friendly means of providing linear motion without any risk of polluting the ocean with oil leaks. The eco-friendly operation of electric actuators can also reduce the extra work required for certain OEMs having to pass specific health and safety regulations.

Important Specifications of Marine 12V Linear Actuators

When choosing an actuator, it’s important to ensure that its specifications are sufficient to meet all your requirements. The primary actuator specifications looked at are:

- Ingress protection

- Force rating

- Physical dimensions

- Travel speed

1. Ingress Protection

Having a sufficient Ingress protection rating ensures a longer product lifespan when exposed to water, and required for marine class linear actuators. We recommend an IP rating of at least IP66 for use on the exterior of boats or pleasure craft. Our range of actuators have options with IP ratings available at IP66 for outdoor use all the way to IP68M dynamic/IP69K static for full submersion. Units rated for IP66 are suitable for most outdoor use as they can withstand dust and moderate liquid ingress. For operating underwater and withstanding high-pressure water jets while static, our PA-10 is suitable as a waterproof linear actuator, with our highest IP ratings of IP68M and IP69K.

Force Rating

We recommend calculating the required force of your application before purchasing an actuator. This is because selecting the right force option is crucial for ensuring smooth operation and long life. An actuator’s dynamic force rating is how much load the actuator can push and pull when the load is applied directly on the shaft. Dynamic force should be selected as something higher than or at least equal to what is required. The static force rating of an actuator is how much load the shaft can hold still when electrical power is shut off. In a circumstance where the actuators are no longer cycling, having the sufficient static force rating will ensure safe operation.

Physical Dimensions

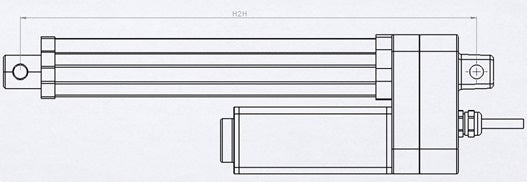

An actuator’s retracted hole to hole (H2H) dimension is the first crucial measurement when determining its physical requirements. This measurement is the distance from the center of the rear mounting hole to the center of the front mounting hole. It is essential to make sure that this dimension lines up with your application’s rear mounting hole center to the front mounting hole center. If the actuator’s H2H is too short for your application’s H2H, we have options to manufacture a custom ordered unit with your required H2H length. However, if the H2H of the actuator is too long for your application, then the application needs to be adjusted or we can help you look for a different model.

H2H retracted length

After verifying that the H2H dimension is suitable, the next step is to make sure that the stroke of the actuator provides the right amount of travel distance. In cases where our stocked stroke sizes are not suitable, we can manufacture a custom unit with the suitable stroke length for your requirements.

Travel Speed

For some use cases, there may be a certain range of speeds that your actuator is required to have. For example, users raising a boat shed with actuators may expect the process to be completed in a relatively fast time. To determine your required speed, the stroke length must be divided by the desired amount of time. For example, a stroke length of 20 inches that needs travel in a maximum of 10 seconds would mean a required speed of at least 2 inches/second. After the minimum speed is confirmed, the next step is to select actuators that have a travel speed faster than or equal to the requirement.

In Summary

Electric linear actuators have great versatility for Marine OEM use as they are available in many different sizes and specifications, whether it be for a boat hatch lift, boat shed, or needed internally. Their ease of use, low maintenance and eco-friendly operation are key reasons they are commonly used in the marine industry.

|

Specifications |

Hydraulic actuators |

Pneumatic actuators |

Electric actuators |

|

Maximum force |

Highest |

Medium |

High |

|

Maximum speed |

Very high |

Very high |

High |

|

Operational efficiency |

40 to 55% |

10 to 25% |

75 to 80% |

|

Life expectancy |

Medium |

Medium |

High |

|

Maintenance |

High |

High |

None |

|

Energy Consumption |

High |

Very high |

Lowest |

|

Operational temperature |

Limited range |

Limited range |

Most flexible |

|

Accuracy and repeatability |

Limited range |

Limited range |

Highest |

|

Space efficiency |

Low |

Low |

Highest |

Actuator comparison table

We offer many different actuators with customizable options to meet your needs. If you have any queries or wish to discuss our products further, please do not hesitate in reaching out to us! We are experts in what we do and want to ensure you find the best solution for your application.

sales@progressiveautomations.com

1-800-676-6123