Industrial and commercial applications come in a variety of different use cases, requiring innovative technology from manufacturers to keep up with their growing demand. Find the ideal solution for your operations in our specialized range of industrial and commercial actuators.

Linear Motion for Industrial Automation Applications

Designed to deliver smooth and reliable movement in any environment for years to come.

2.41%

Average YoY Cost Reduction99.8%

Perfect QC Pass Rate100%

Powered By Renewable EnergyWe're More than a Supplier: Adding Value Beyond the Product.

With an unwavering commitment to mutual success, we're a flexible partner that adds value at every step along the component lifecycle.

Consistently High Product Quality

Get ultra-low product failure rates with a quality control regime that's reliable, stringent, adaptive and systematic.

Progressive Automations is ISO9001.2015 Certified

Get quality you can trust. Work with a partner that's truly committed to continuous improvement.

Flexible Pricing with Pass-Through Cost Reductions

Unlock savings with ramp-up friendly, inflation-resistant pricing, where scale-related savings pass directly on to you.

We Deliver on Time, Every Time.

Even with supply chain challenges becoming more common, we've maintained a 98% on-time shipment rate since 2017.

Zero Lead Times & Unparalleled Flexibility with Smart Logistics

Avoid costly air freight and production delays. We get custom units to your dock in days, not months.

Automated testing equipment is essential in manufacturing, electronics, and other industries for efficient and accurate product and component testing. Actuators provide precise control and automation to enhance testing speed, consistency, and reliability.

Commercial kitchens are dynamic environments where food is prepared and cooked on a large scale. Electric actuators play a crucial role in automating various kitchen equipment to enhance efficiency, precision, and safety. Operations include adjusting ventilation systems, height-adjustable workstations, and cabinet doors.

Filtration machinery ensures the purity and quality of liquids and gases. Electric linear actuators enhance these machines' functionality by providing precise control, advanced automation, and robust safety features. They adjust filter elements, control flow rates, and integrate with automated systems, ensuring consistency and efficiency.

Conveyor systems are essential in modern manufacturing and warehousing, designed to transport materials and products efficiently and safely.

Electric linear actuators significantly enhance the functionality of these systems by providing precise control, advanced automation, and robust safety features.

Retail automation is essential in modern retail environments, designed to enhance efficiency and customer experience by automating various tasks. Electric linear actuators significantly enhance the functionality of retail automation systems by providing precise control, advanced automation, and robust safety features.

Packaging Machines are crucial in modern manufacturing and logistics, designed to package products efficiently and safely. Electric linear actuators significantly enhance the functionality of these machines by providing precise control, advanced automation, and robust safety features.

Bar Feeders are essential in modern manufacturing, designed to transport materials and products efficiently and safely. Electric linear actuators significantly enhance the functionality of these machines by providing precise control, advanced automation, and robust safety features.

TESTIMONIAL

"Progressive offers off-the-shelf units and custom options that could match our needs better while accommodating a faster turnaround time”

Jett Rubin Medical Device Manufacturer

Custom Linear Motion for Industrial Automation

Actuator Customization

Transform your projects with actuators built for your unique challenges. Whether you're transitioning from hydraulics or facing issues like water ingress, we understand that every application is unique.

Our engineers help you craft solutions that fit your exact specifications, with flexible minimum quantities, turning complex requirements into precise, efficient designs.

As your needs evolve, so do our solutions - we're here for the long haul, and you're gaining a partner dedicated to your success.

Case Studies

CASE STUDY

UV Hammer for Dimer

Dimer UV are experts in inventing cutting-edge germicidal UV light disinfection systems. The company's mission is to set new, higher standards for public health in transportation and shared spaces.

When developing the UV Hammer, Dimer needed to find the right linear actuator to maneuver the unit’s UVC wing assembly. Other suppliers Dimer worked with in the past were not only more expensive and less reliable, but also unwilling to troubleshoot issues when they arose. From there, Dimer turned to Progressive Automations.

Make The Project Of Your Dream

Boat Engine Hatch

By using quality custom linear actuators and advanced control systems for synchronization, Progressive Automations offers convenient, reliable, and user-friendly automation solutions that enable customers to protect their engine hatches through automated hatch covers. In this case study, we will cover the process, challenges, and solutions involved in bringing automated hatch covers to life for boats, yachts, and other sea vessels.

DISCOVER MORE

Blog post

440 Stainless Steel: The Ultimate Guide to High-Performance Martensitic Steel

Blog post

2035 Vision: The Convergence of Smart Manufacturing, Clean Energy, and AI Reshaping Our Future

Blog Post

Download The Testing Guide

This guide will outline essential steps and the process of evaluating a sample actuator. We include a checklist to ensure all the requirements are met.

Blog Post

Top 10 Questions We Get from Our OEM Customers

You will find useful FAQ from OEM Customer as for your search for a parts supplier of electric linear actuators.

Application

Automated Testing Equipment

Automated testing equipment actuators provide precise control and automation to enhance testing speed, consistency, and reliability.

Challenges

Ensuring precise and accurate positioning of test probes and sensors to maintain testing integrity in automated test equipment.

Safe actuator operation is crucial to protect personnel and equipment during testing.

Solutions

Implement high-precision electric actuators equipped with advanced feedback systems like hall sensors.

Choose robust actuators with high IP ratings constructed from durable materials such as stainless steel or aluminum.

Incorporate comprehensive safety features such as emergency stops, limit switches, and overload protection.

Benefits

By automating the positioning and movement of test probes and sensors, actuators ensure each test is conducted under identical conditions.

Robust designs ensures reliability and minimal maintenance.

Additionally, electric linear actuators enable the validation of increasingly complex products.

Automated Testing Equipment

Precise Positioning

Model

PA-13 Linear Actuator

Function

Electric linear actuators provide highly accurate movement and positioning of test probes and sensors

Benefits

Ensures that each test is conducted under identical conditions, leading to reliable and reproducible test results crucial for quality control and validation.

PA-13 Linear Actuator

The PA-13 High Force Industrial Linear Actuator is one of the strongest units in our line-up.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Customizable for Hall Sensors

- Durable Construction

- IP66 Water Protection

Request Custom Specs

Application

Commercial Kitchens

Electric actuators play a crucial role in automating various kitchen equipment including adjusting ventilation systems, height-adjustable workstations, and cabinet doors.

Challenges

Commercial kitchen equipment must withstand frequent use in harsh conditions, such as heat, moisture, and cleaning chemicals.

Actuators need to integrate seamlessly with a wide range of kitchen equipment, including ventilation systems, ovens, dishwashers, and storage units.

Close proximity to kitchen staff and customers requires low noise operation.

Solutions

Use coatings that resist corrosion and wear.

Select actuators designed with robust materials and high IP ratings.

Selecting actuators with simple electrical operation and/or compatible communication protocols with versatile mounting options.

Choose actuators with quiet operation and add noise dampeners as needed.

Benefits

By integrating electric linear actuators, commercial kitchens can streamline their processes, reduce manual labor, and improve overall productivity and safety.

Low maintenance requirements leads to lower costs, less downtime for equipment repairs, and longer equipment lifespan without frequent interruptions.

Commercial Kitchens

Adjusting Ventilation Systems

Model

PA-01 Linear Actuator

Function

Electric linear actuators are used to regulate the position of vents and hoods in kitchen ventilation systems. This includes opening, closing, and adjusting the angle of vents to control airflow.

Benefits

Maintaining optimal air quality is crucial in commercial kitchens to ensure a safe and comfortable working environment. Proper ventilation helps remove smoke, steam, and odors, reducing the risk of fire hazards and ensuring compliance with health and safety regulations. Actuators allow for precise and automated adjustments, which can respond quickly to changes in kitchen activity levels.

PA-01 Linear Actuator

Compact in size with medium force capabilities, the PA-01 Linear Actuator has a low current draw ideal for power efficiency.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP65 Water Protection

Request Custom Specs

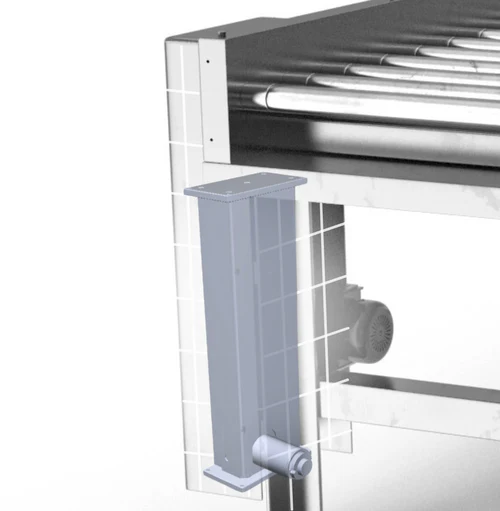

Application

Filtration Machinery

Electric linear actuators enhance these Filtration machinery functionality by adjusting filter elements, control flow rates, and integrate with automated systems, ensuring consistency and efficiency.

Challenges

Filtration equipment operates in diverse environmental conditions, including moisture, dust, and varying temperatures.

Must operate efficiently to minimize energy consumption and operational costs.

Achieving precise control and accurate positioning of filter elements is critical for maintaining consistent filtration efficiency.

Solutions

Use actuators with high IP ratings, robust construction materials, and protective coatings.

Choose actuators with energy-efficient designs and features, such as low-power standby modes and optimized motor technologies.

Implement actuators with high-resolution feedback systems, such as encoders or hall sensors.

Benefits

Actuators reduce the need for manual labor, increasing both productivity and safety in industrial settings.

Consuming only the necessary amount of energy to perform their tasks, their energy-efficient operation contributes to reducing overall operational costs and environmental impact.

Filtration Machinery

Controlling Filtration Pressure

Model

PA-10 Linear Actuator

Function

Actuators adjust pressure settings to maintain optimal operating conditions in filtration systems.

Benefits

Extended equipment lifespan and reliable performance in continuous filtration processes. Controlling pressure enhances filtration efficiency, ensuring effective particle capture and separation without compromising throughput or system integrity.

PA-10 Linear Actuator

The PA-10 is a highly efficient waterproof actuator designed to handle a wide range of applications.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP68M Waterproof Protection

Request Custom Specs

Application

Conveyor Systems

Conveyor systems are essential in modern manufacturing and warehousing, designed to transport materials and products efficiently and safely.

Challenges

Conveyor belts and automated conveyor systems often handle varying loads, which can strain the actuators if not properly managed.

Maintaining precise positioning and movement is critical in applications requiring exact placement of items.

Harsh industrial environments, such as those with high dust, moisture, or extreme temperatures, can affect service life.

Solutions

Implement load sensors and distribution algorithms to ensure even load distribution.

Utilize actuators with high-resolution positional feedback sensors and control systems to achieve precise positioning.

Choose materials and coatings that can withstand corrosive environments and select models with high IP ratings.

Benefits

Electric linear actuators streamline operations by adjusting loading mechanisms, controlling movement, and integrating with automated systems, ensuring consistent and efficient material handling.

Additionally, their integration reduces the need for manual labor, increasing both productivity and safety in industrial settings.

Conveyor Systems

Automated Sorting

Model

PA-10 Linear Actuator

Function

Actuators control the movement of sorting mechanisms to direct items to specific locations.

Benefits

Automated sorting increases throughput and accuracy, reducing manual labor and error rates, and enhancing overall operational efficiency.

PA-10 Linear Actuator

The PA-10 is a highly efficient waterproof actuator designed to handle a wide range of applications.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP68M Waterproof Protection

Request Custom Specs

Conveyor Systems

Height Adjustment

Model

LG-12 Lifting Column

Function

Lifting columns change the height of conveyor sections to accommodate different products or processing requirements.

Benefits

Adjustable height capabilities improve flexibility, allowing the system to handle a variety of product sizes and types, and enhance ergonomic conditions for operators.

LG-12 Lifting Column

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

Request Custom Specs

Application

Retail Automation

Electric linear actuators significantly enhance the functionality of retail automation systems by providing precise control and advanced automation.

Challenges

Automated retail technology requieres achieving high precision and accuracy in movements can be difficult, especially for tasks requiring fine adjustments.

Reducing noise levels is necessary to maintain a pleasant retail environment. Solutions must fit in tight spaces while maintaining performance.

Solutions

Implement advanced control algorithms and high-resolution sensors to enhance the precision of actuator movements.

Utilize noise-dampening materials and actuator designs that operate quietly. Select compact yet powerful actuators.

Employ miniaturized components and optimize the design for space efficiency.

Benefits

Electric linear actuators streamline operations by adjusting shelving mechanisms, controlling movement, and integrating with automated systems, ensuring consistent and efficient retail operations.

Their integration reduces the need for manual labor, increasing both productivity and safety in retail settings.

Retail Automation

Security Systems

Model

PA-04 Linear Actuator

Function

Electric linear actuators are used in automated security barriers and locking mechanisms.

Benefits

Enhances store security by providing reliable and automated control over access points, reducing the risk of theft and unauthorized entry.

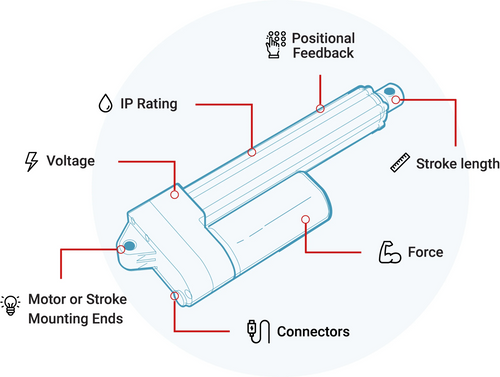

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our lineup. It is popular in a variety of use cases including those found in the industrial & commercial industries.

Key Features

- Versatile Force Rating

- Low Noise

- High Speed

- Maintenance Free

- Excellent Price/Performance Ratio

- IP66 Water Protection

Request Custom Specs

Application

Packaging Machines

Electric linear actuators significantly enhance the functionality of Packaging Machines by providing precise control, advanced automation, and robust safety features.

Challenges

Ensuring actuators withstand the mechanical stresses and vibrations inherent to industrial packaging machines.

Protecting actuators from dust, moisture, and temperature variations in diverse packaging environments.

Mitigating noise and vibrations generated by actuators during packaging operations.

Solutions

Using robust materials for construction and integrating shock-absorbing mechanisms within actuators.

Applying appropriate enclosures and seals enhances resistance to environmental elements.

Select actuators with high IP ratings for added protection. Incorporating noise-dampening materials and actuators with low noise ratings.

Benefits

Electric linear actuators streamline operations by adjusting packaging mechanisms, controlling movement, and integrating with automated systems, ensuring consistent and efficient packaging.

Additionally, their integration reduces the need for manual labor, increasing both productivity and safety in industrial settings.

Packaging Machines

Precise Positioning

Model

PA-01 Linear Actuator

Function

Electric linear actuators precisely control the position of packaging components such as cutting blades, sealing bars, and labeling heads.

Benefits

This precision ensures accurate cuts, seals, and label placements, reducing waste and ensuring high-quality packaging.

PA-01 Linear Actuator

Compact in size with medium force capabilities, the PA-01 Linear Actuator has a low current draw ideal for power efficiency.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP65 Water Protection

Request Custom Specs

Application

Bar Feeders

Electric linear actuators in Bar Feeders significantly enhance the functionality of these machines by providing precise control, advanced automation, and robust safety features.

Challenges

Bar feeders often deal with varying load sizes and weights, requiring actuators to handle different force levels efficiently.

Exposure to harsh conditions like dust, moisture, and temperature extremes.

Meeting safety standards and ensuring safe operation in industrial environments is essential.

Solutions

Use advanced compatible control algorithms and variable force settings.

Incorporate load sensors to dynamically adjust the force output. Select robust construction materials and actuators with high IP ratings to ensure sufficient protection.

Choose actuators that comply with relevant safety certifications and standards like CE, UL, and ISO.

Benefits

Electric linear actuators streamline operations by adjusting loading mechanisms, controlling movement, and integrating with automated systems, ensuring consistent and efficient material handling.

Additionally, their integration reduces the need for manual labor, increasing both productivity and safety in industrial settings.

Bar Feeders

Material Feeding Control

Model

PA-04 Linear Actuator

Function

Electric linear actuators control the precise feeding of materials (such as bars or rods) into machining processes.

Benefits

Accurate positioning of the bar feeder mechanism, maintaining consistent material feeding rates. This function is critical for automated machining operations, where precise material handling enhances product quality and process efficiency.

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our lineup. It is popular in a variety of use cases including those found in the industrial & commercial industries.

Key Features

- Versatile Force Rating

- Low Noise

- High Speed

- Maintenance Free

- Excellent Price/Performance Ratio

- IP66 Water Protection

Bar Feeders

Height Adjustment

Model

LG-12 Lifting Column

Function

Lifting columns facilitate the positioning and adjustment of the bar feeder components.

Benefits

They allow for automated adjustments of feed length, bar diameter, and positioning within the machining setup. This capability supports quick setup changes and reduces downtime between production runs, optimizing overall equipment efficiency.

LG-12 Lifting Column

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated