Micro Precision Servo Actuator - RS-485

Voltage

Stroke

Force

IP Rating

Feedback

PA-MC1

PA-07

PA-12-T

PA-12-R

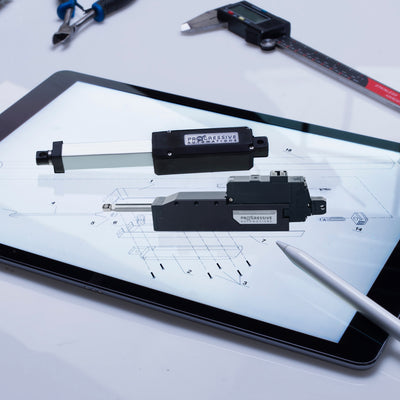

Our micro linear actuators are defined by their small design, which makes them ideal for projects with limited spacing. They are quite popular thanks to their versatility and the range of applications they are suited to. Our micro actuators are known for their precision control options and force capabilities which, while impressive compared to their size, are perfect for those who require it minimally. Popular applications of micro linear actuators include the robotics and automotive industry, where these actuators can be seamlessly integrated into their interior and exterior systems. Most of our products are extremely easy to install and maintain as plug-and-play solutions, with our PA-07 micro linear actuators being no exception. For communicating with our PA-12 micro linear actuators, we offer RS-485 and TTL/PWM communication options to ensure high precision through feedback.

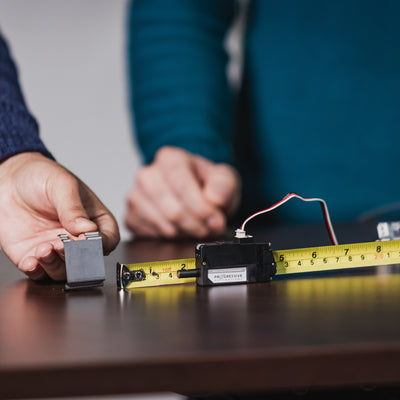

With stroke length options measuring from 0.5” to 12” our micro actuators can fit into the most limited of spaces without compromising on performance. Our servo motor options have dynamic force ratings that can reach up to 22.48lbs.

These actuators have a low current draw, allowing users to install more units to a single control box without any additional equipment.

Thanks to the servo motor inside the PA-12-R and PA-12-T, their precision accuracy goes up to 100um. Communications such as RS-485 or TTL/PWM give you full control over their position, speed, and synchronized movement.

We have data sheets, user manuals, 3D models, wiring diagrams and more in our Resources and Learning Center sections.

Yes, our actuators can be seamless replacements for most applications. Please contact us if you are unsure of which actuator to opt for. You will need to know the voltage rating, force rating, and stroke length needed before we can give a recommendation for a replacement actuator.

Our table lift weight capacities are dependent on the unit you are choosing. The minimum weight capacity will range from 180 lbs to 1300 lbs per leg, however, the lifting force of a system also depends on how many legs you install. Assuming equal weight distribution when using multiple legs, you can calculate total system weight capacity by multiplying the number of legs you have with the weight capacity of one leg.

Yes. However, it is important to have sufficient voltage and current to be applied to your actuator. Here is an article that may help you further: How to Choose the Right Power Supply for your Linear Actuator

As we are primarily manufacturers and distributors, we have a limited amount of sample codes available. While we cannot provide specific coding for your application, we do have a growing list of sample Arduino codes. To access these sample codes, please click here.

No. However, we have a large variety of control boxes to choose from for each actuator. Alternatively, you may also use rocker switches as a form of motion control.

Yes, however, you need to ensure your control box can provide sufficient current draw and compatible voltage. Otherwise, you risk damaging your actuator(s).

Please click here for a list of 3D CAD models available.