- Introduction to How Actuators Work

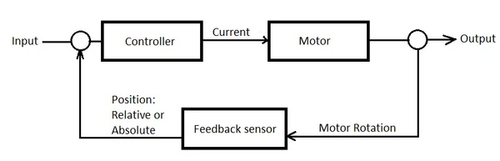

- Positional Feedback Mechanisms

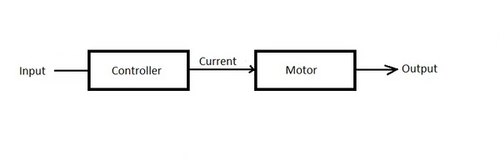

- Types of Control Systems for Actuators

- Feedback and Error Correction

- Control Boxes for Linear Actuators

Introduction to How Actuators Work

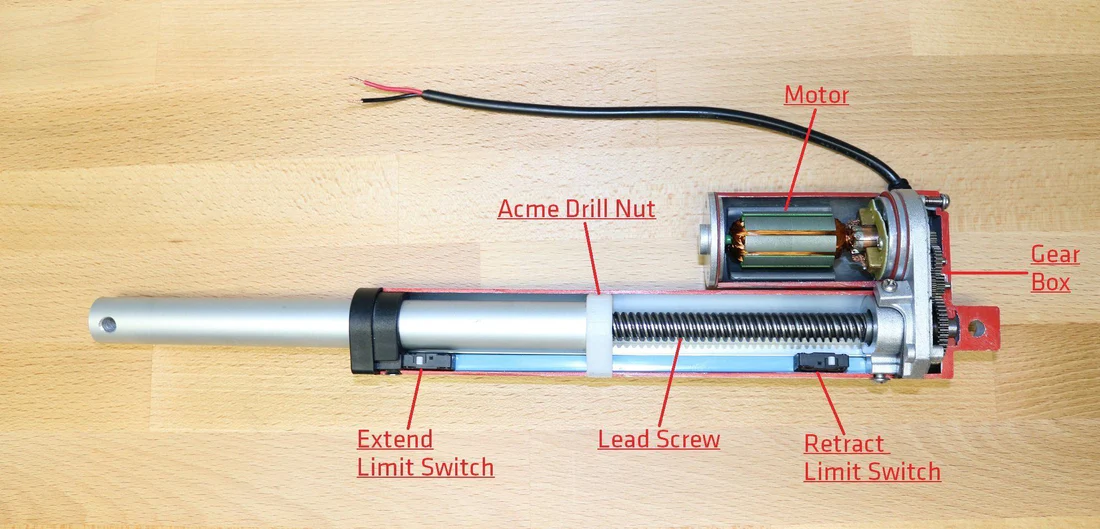

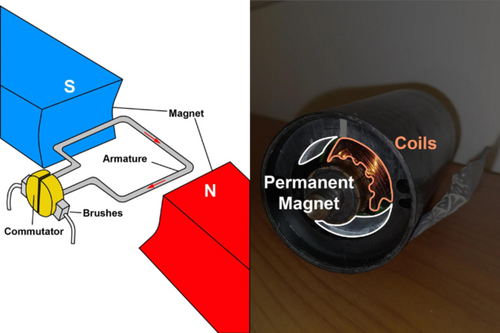

In electric linear actuators, electric current is used to produce rotational motion in an electric motor

that’s mechanically linked to a gearbox and utilizes a lead

screw to cycle the actuator’s shaft attached to an ACME drill nut for linear motion. Control systems for actuators have developed significantly over the years, enhancing the versatility and functionality of these devices. Linear actuators can be operated through various means and control mechanisms including:

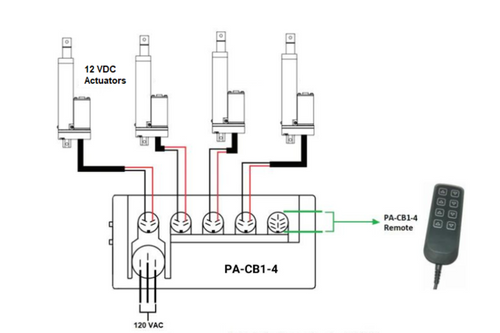

• Wireless controllers - offer users the convenience of remote control operation from a distance without the need for physical cables.

• Wi-Fi and Bluetooth capable controllers - allow for integration into smart systems and access through mobile devices, providing user-friendly interfaces and the ability to adjust settings remotely and precisely.

These advancements in actuator technology and control systems have broadened the scope of their applications, making them indispensable in modern automated systems. Whether it's adjusting windows in vehicles, operating heavy duty agriculture equipment, or automating home appliances, actuators continue to be pivotal in translating electrical signals into physical action.

Understanding Control Systems for Actuators

The primary purpose of these systems is to ensure that actuators perform accurately, efficiently, and reliably according to predefined parameters.

The significance of control systems in actuator operation cannot be overstated, particularly when it comes to achieving precise and efficient motion control. These systems are crucial for several reasons:

1. Precision: Control systems allow for the fine-tuning of actuator movements to achieve high levels of repeatability and accuracy. This is essential in applications where exact positioning is critical, such as in robotic surgery or aerospace engineering.

2. Efficiency: By optimizing the way actuators respond to commands, control systems reduce energy consumption and minimize wear and tear. This not only extends the lifespan of the actuator but also enhances the overall efficiency of the system it operates within.

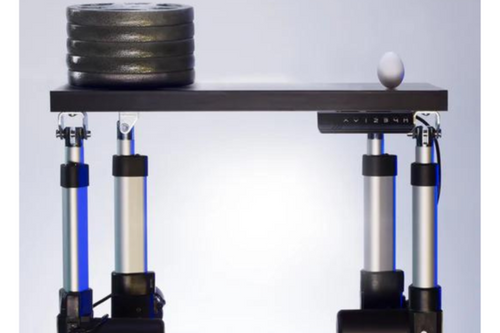

3. Adaptability: Feedback mechanisms can adjust the behavior of compatible actuators in real-time by analyzing the positional feedback from compatible actuators. This adaptability is vital in dynamic environments where conditions change rapidly, such as in automated manufacturing processes or when multiple actuators are experiencing unequal weight distribution.

5. Safety features: Programmed safety features such as overload protection help in preventing damage to an actuator or the application by stopping operation after the control box has detected an excessively high electric current draw. Another safety feature found in control boxes includes overheat protection to stop operation after a certain amount of cycling time to ensure operation stays within the duty cycle ratings of an actuator, thus avoiding motor burnouts. Control systems are fundamental to the functionality of actuators, providing the necessary intelligence and adaptability to ensure precision, efficiency, safety, and effective motion control. Their role is pivotal in the expanding realm of automation technology, where movement precision is often the cornerstone of operational success.

Components and Types of Control Systems

Key Components of a Basic Control Box

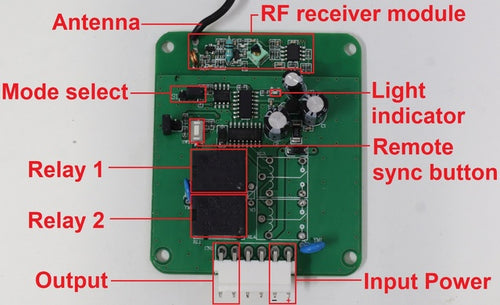

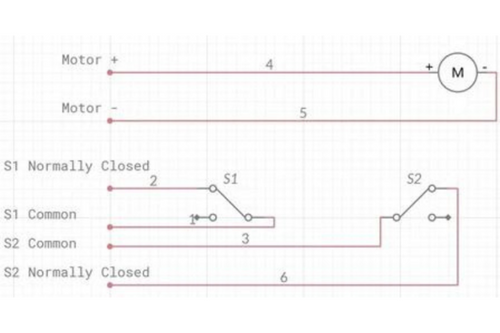

In a basic control box designed for electric linear actuators, each component plays a crucial role in ensuring efficient operation. Here’s a breakdown of these major components, their functions, and the purposes they serve:1. Relays: Relays act as switches that control the high-power electrical circuit using a low-power signal. For control boxes designed to manage 2-wire actuators, two relays are essential for reversing the polarity of the voltage applied across the actuator’s two wires, which in turn changes the direction of the movement. This allows for bidirectional control in a simple setup to extend and retract the actuator.

2. Input Channels: Input channels are interfaces through which the control system receives electrical signals from external sources such as power supplies or signals from wired remotes. Control boxes that operate with positional feedback may also receive input from the sensors of an actuator. These channels process the inputs from the user and/or sensors to determine how the actuator should operate, making them fundamental for initiating and controlling actuator movements based on specific requirements.

3. Output Channels: Output channels deliver control signals from the controller to the actuator or other components like relays. Control boxes that operate with positional feedback may also output electric current so that the sensors of an actuator have the power to operate. These channels are crucial for executing the commands determined by the control system, directly influencing the actuator’s behavior.

4. Remote Sync Button: This button is used to synchronize the control system with a remote control device. It ensures that the remote inputs are recognized and processed by the control system, facilitating convenient and flexible operation from a distance.

5. Light Indicator: Light indicators provide visual feedback about the system’s status. They can be an indicator for power on/off, operation modes, error states, or signal reception, which helps in monitoring and troubleshooting the system without needing complex diagnostic tools.

6. Mode Select: This feature allows the user to switch between different operating modes of the control box, such as momentary or non-momentary controls. In momentary mode, a remote’s button must be continuously held in the active position for the device to operate. Once you release the switch, the device stops functioning. Non-momentary mode works like a switch that remains in its last set position until it is changed again, regardless of whether it is being pressed. This means that once activated, the device continues to operate until the switch is manually turned off.

7. Antenna: The antenna is part of control boxes that have a wireless communication setup. Antennas are used to enhance the signal range and quality between the control system and remote control devices or between interconnected systems. It is crucial for maintaining robust communication in environments where direct wiring is impractical or undesirable.

8. RF Receiver Module: This module receives radio frequency signals sent by wireless remote controls. It decodes these signals into actionable commands that the control system can understand and act upon. The RF receiver module is essential for wireless control setups, allowing for remote operation of the actuator without physical contact. Together, these components form a comprehensive control system for 2-wire actuators, each serving a specific function that contributes to the overall effectiveness and efficiency of the actuator’s operation. This system not only allows for precise control over the actuator’s movements but also enhances the user interface and interaction, making it adaptable to a wide range of applications.

Positional Feedback Mechanisms

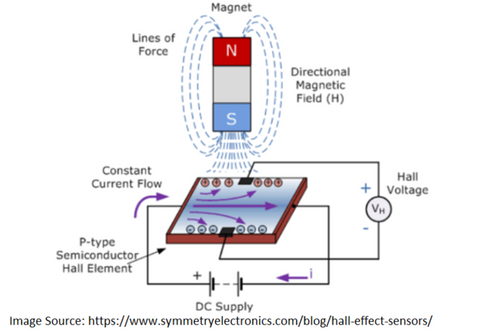

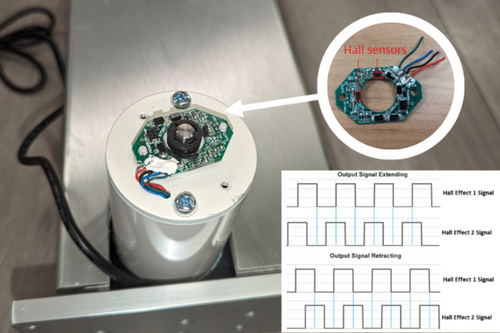

Hall effect sensors

The Hall Effect theory, Edwin Hall (who discovered the Hall Effect), stated that whenever a magnetic field is applied in a direction perpendicular to the flow of electric current in a conductor, a voltage difference is induced. This voltage can be used to detect whether a hall effect sensor is in the proximity of a magnet.

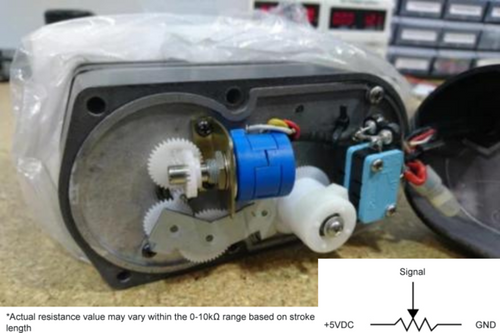

Potentiometers

A potentiometer provides a variable resistance that is proportional to the position of the actuator. Gears are often linked between the potentiometer’s knob and the actuator’s rotating motor. As the actuator moves, the resistance value changes, which can be measured and converted into position data. This information is then used by a control system to make fine adjustments to the actuator's position, enhancing accuracy.

Limit Switch Feedback

The purpose of limit switch feedback signals is to allow a system to determine whether the actuator has physically tripped the internal limit switches. This kind of feedback is simple and useful for applications that mainly just require information on whether the actuator has reached the fully extended or fully retracted positions.Types of Control Systems for Actuators

One example of a simple open-loop system includes a momentary rocker switch wired to a linear actuator. This requires an operator to physically press and hold the switch for the actuator to continue cycling and letting go of the switch before the actuator has reached the end of travel will result in the actuator stopping motion mid-way.

The choice of control system and its components significantly impacts actuators' functionality and performance optimization. By integrating effective feedback mechanisms and selecting the appropriate control system type, actuators can be optimized for a wide range of applications, ensuring both precision and reliability in their operation.

Feedback and Error Correction

Variables That Control Systems Correct For

1. Position: Control systems help ensure that an actuator reaches and maintains the desired position accurately by comparing the user’s position to the actual position reading from the positional feedback sensors. Examples include when standing desk users press a controller’s button to have actuators travel to a specific preset memory position to adjust their workspace from the seated to standing height.

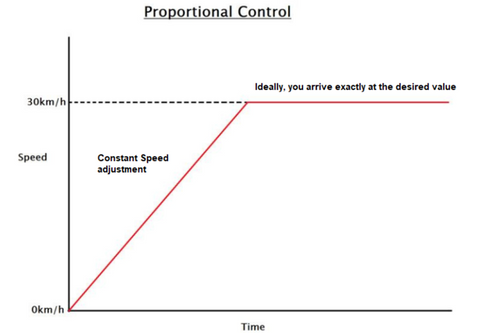

2. Speed: Reading positional feedback and dividing the distance traveled by how much time had passed will result in travel speed. Some control systems allow for adjustable speed settings through PWM (Pulse Width Modulation), enabling the actuator to move at different speeds based on the application's requirements. This is useful in applications where varying speeds are necessary such as for actuators driving the motion of flight simulators.

3. Force: Certain control systems can regulate the amount of force exerted by actuators, ensuring that it operates within safe limits and prevents damage to the system or surrounding components. By measuring the electric current draw, control systems can gauge approximately how much force is being exerted by linear actuators. This feature is useful for linear actuators that open and close windows to shut off power and stop applying force in case a person's hand or obstacle is blocking the path of travel.

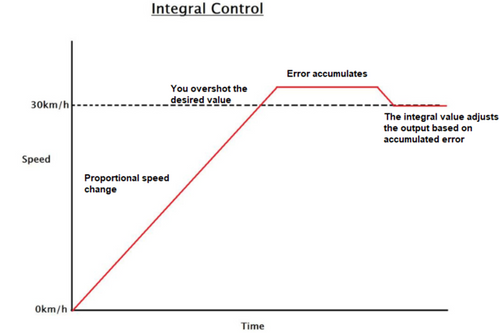

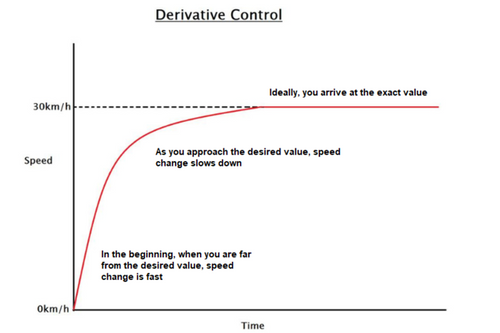

Types Of Control Strategies

Choosing the Right Control System

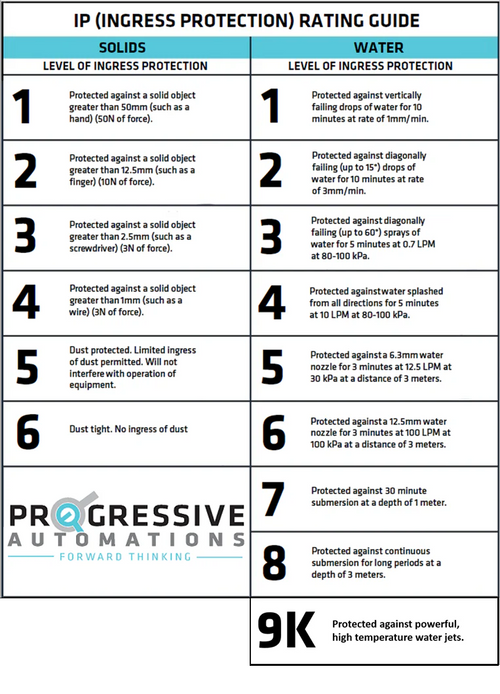

• Ingress Protection

• Compatibility

• Budget

1. Ingress Protection: Assess the specific environmental requirements of your application to determine the type of control systems needed. The PA-33 control box for example has an ingress protection rating of IP65 for dust and water resistance. An ingress protection rating of IP65 or higher is recommended for control systems exposed to outdoor elements such as rainwater, dust, and debris. 2. Compatibility: Ensure that the control system is compatible with the electric linear actuators you have chosen or are currently using to ensure seamless integration. Check if your actuator has the matching communication protocols/positional feedback to the controllers you were considering. For example, the PA-12-T (TTL/PWM) and PA-12-R (RS-485) Micro Precision Servo Actuator provide precise position control with positional accuracy up to 100 um and require advanced communication protocols for such performance. Another thing to consider is whether the type of motor your actuator has will be compatible with a control system. Continuously operating brushless motors such as those found in our custom ordered PA-14 actuators would require control boxes compatible with their operation such as the LC-241 control box. To see which of our control boxes and actuators are compatible with each other, check out our control box comparison and compatibility charts linked below: https://7717445.fs1.hubspotusercontent-na1.net/hubfs/7717445/PDF%20Manuals/Desk%20Accessories/Control%20Boxes%20Compatibility%20Chart%202023.pdf https://7717445.fs1.hubspotusercontent-na1.net/hubfs/7717445/PDF%20Manuals/Desk%20Accessories/Control%20Boxes%20Comparison%20Chart-1.pdf 3. Budget: Consider if there were any budget constraints for the project and choose a control system that offers the best value for your investment while meeting your performance requirements. For example, simple indoor projects that do not require high precision would work without any issues by wiring a basic rocker switch without high ingress protection to control a 2-wire mini linear actuator at an affordable price.

Hall Effect Type Control Boxes

Read our blog on applications for the FLTCON control boxes for more information.