Electric linear actuators provide a reliable lift on the engine hatch, making it easier to access the heart of the vessel. The engine hatch protects the engine from seawater splashes which can corrode and cause further damage to the engine’s life span. To ensure the boat engine is well protected, the hatch cover tends to be large and sometimes quite heavy. Opening this alone can be difficult and at times, impossible to do alone. In such cases, a motorized lift for the engine hatch would provide easy access to the engine while retaining the protection needed against the elements.

INDUSTRY AND APPLICATION

An Easy Solution to Open and Close Engine Hatches on Boats

Thanks to the consistent linear motion of electric linear actuators, they are regularly used for lifting or opening doors, windows and as covered in this project: boats, yachts, and other sea vessels.

CHALLENGES

We were approached by our customer who needed an automated hatch cover designed and developed for his boat. We first identified three major challenges.

Mounting Point

There was limited space to mount the actuator, and we also needed to consider the path the unit would take when the hatch cover opens and closes. We needed to ensure there was no obstruction to motion when the unit operates and when fully opened.

Heavy Lifting

To lift the hatch cover safely, the actuators needs to have a sizeable buffer margin on the force capabilities. For example, to lift a 400 lbs engine hatch cover, you will need at least 500 lbs of force to operate safely. The mounting position also has to be accounted for.

Emergency Release

In the unlikely event of an engine hatch lift failure or loss of power, you should still be able to access the engine compartment. The lift needs to release the lock on the hatch without compromising the lifting capability of the actuator.

SOLUTION

After careful examination of our customers’ application, we found the perfect unit.

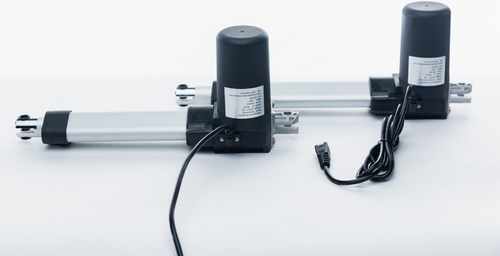

The PA-04-HS with the push only option unit was able to resolve all the issues.

- With the hall effect sensor, we were able to use two units in synchronous with each other.

- The feedback signal provided by the sensor allows the control system to monitor the positions of both units continuously and calibrate the motion of each actuator to match the other. With this, our customer was able to mount the actuators on each side of the engine hatch instead of in the middle, which would obstruct the normal path into the engine compartment.

- Moreover, two units working together to lift the engine hatch provides additional lifting capability – the combined power of two PA-04 can reach over 2500 lbs of force.

-

The push-only custom option was added to ensure that the user has access to the engine compartment no matter what. This modification allows the shaft of the actuator to detach from the ACME screw nut in the extending direction only, thus pushing the shaft forward. The ACME screw nut will then retract along the screw bit itself, but the weight of the engine hatch cover will always push the shaft against the screw nut, so the hatch cover will still close as normal.

In the event of power loss or lift failure, the hatch can be manually lifted without any damage to the actuators as the actuator shaft is not attached to the screw nut.

RESULTS

Well protected engine

18 Month Warranty in case of unit failures

Reduced effort to open and close the hatch cover

The solution was implemented on multiple lines of products

PA Product Used

PA Product Used

Hall Effect Sensor Actuator IP66

Model: PA-04-HS

- Voltage: 12 VDC, 24 VDC

- Stroke: 6-40 inch

- Force: 400 lbs