Electric linear actuators offer many benefits in lawn mower applications as they can significantly improve operational convenience, efficiency, and user ergonomics. Being available in many different sizes, specifications, and customization options allows for the versatility to handle a range from small to large scale ride on lawn mower use cases. This article will cover the important aspects of electric linear actuators for lawn mowers such as their important specifications, popular use cases, and a summary of their top benefits.

Important Specifications

For electric linear actuators, there are a few important specifications that must be considered to ensure they meet all the requirements of any given lawn mower.

- IP rating (ingress protection)

- Force rating

- Physical dimensions

- Travel speed

- Positional feedback

IP Rating

Having a sufficient IP rating for ingress protection ensures a longer product lifespan when exposed to outdoor elements. We recommend an IP rating of at least IP65 for exterior lawn mower use. Our range of actuators has options with IP ratings available at IP66 for outdoor use to IP68M dynamic/IP69K static for full submersion. Units rated for IP66 are suitable for most outdoor use as they can withstand dust and moderate liquid ingress. Our highest IP ratings of IP68M and IP69K can be found in our PA-10 waterproof linear actuator capable of operating underwater and withstanding high-pressure water jets while static.

Force Rating

We recommend calculating the required force of your application before purchasing an actuator as selecting the right force option is crucial for ensuring smooth operation and long life. An actuator’s dynamic force rating is how much load the actuator can push and pull when the load is applied directly on the shaft. Dynamic force should be selected as something higher than or at least equal to what is required. The static force rating of an electric linear actuator is how much load the shaft can hold still when electrical power is shut off. In a circumstance where the actuators are no longer cycling, having a sufficient static force rating will ensure safe operation.

Physical Dimensions

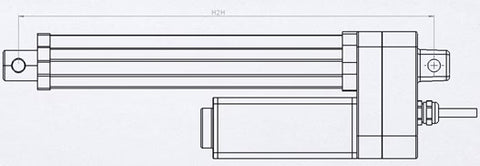

An actuator’s retracted hole to hole (H2H) dimension is the first crucial measurement when determining its physical requirements. This measurement is the distance from the center of the rear mounting hole to the center of the front mounting hole. It is essential to make sure that this dimension lines up with your application’s rear mounting hole center to the front mounting hole center. If the actuator’s H2H is too short for your application’s H2H, we have options to manufacture a custom-ordered unit with your required H2H length. However, if the H2H of a linear actuator is too long, then the application needs to be adjusted or we can help you look for a different model.

After verifying that the H2H dimension is suitable, the next step is to make sure that the stroke of the actuator provides the right amount of travel distance. In cases where our stocked stroke sizes are not suitable, we can manufacture custom solutions with the suitable stroke length for your requirements.

Travel Speed

For some use cases, there may be a certain range of speeds an electric linear actuator is required to have. For example, users raising the cutter blades of a lawn mower with linear actuators may expect the process to be completed in a relatively short time. To determine your required speed, the stroke length must be divided by the desired amount of time. For example, a stroke length of 20 inches that needs travel in a maximum of 10 seconds would mean a required speed of at least 2 inches/second. After the minimum speed is confirmed, the next step is to select actuators that have a travel speed faster than or equal to the requirement.

Positional Feedback

When multiple linear actuators are required to travel synchronously, we recommend models with positional feedback such as hall effect sensors. This is because they have hall effect feedback that goes to a control box which would then be able to make the needed corrections if one side travels at a different speed from the other. Differing speeds can sometimes happen from slightly unequal weight distribution or the speed tolerance from the DC motors (+/- 10%) in the actuators. Output signals for indicating positional information are also crucial for applications that require memory preset functions for precision adjustments when traveling to a required position.

Popular Use Cases

There are many ways ride on lawn mowers utilize electric linear actuators. Just to name a few examples, electric linear actuators have been used to drive the linear motion for:

- Seat Recline Angle Adjustments

- Seat Height Adjustments

- Automatic Engine Hatches

- Steering Wheel Tilt and Height Adjustments

- Positioning Cutter Blades and/or Deck

Seat Recline Angle & Height Adjustments

Promoting proper posture and comfortable user ergonomics throughout the day is well known for boosting productivity and results. The seat height and recline angle adjustments driven by electric linear actuators help make this possible in a convenient way through the push of a few buttons. Steering wheel tilt and height adjustments also share the similar goal of ensuring the operator can adjust to their preferred positions for comfort and ergonomics.

Automatic Engine Hatches

Engine hatches may come with gas-assisted springs that automatically open in 1 direction but require manual operation by hand for the other direction of travel. Although this is an improvement from being completely manual, electric linear actuators offer more convenience since they can move in 2 directions to open and close an engine hatch automatically. Options for wired and wireless controls for electric linear actuators are available through our large range of controllers.

Positioning Cutter Blades and/or Deck

When mowing a lawn, the tilt and height adjustments of cutter blades are crucial to ensure optimum mowing results. Certain lawn mowers are designed with a deck where the cutter blades have coverage while other lawn mowers may have more exposed-style cutter blades. By adjusting the deck and/or cutter blades to the right positions with electric linear actuators capable of precision adjustments, operators can achieve much more consistent results which reduces mowing frequency year-round.

Summary of Top Benefits

The top benefits found in electric linear actuators such as versatility, durability, and high-performance capabilities make them popular solutions in all types of lawn mower applications. Being self-lubricated internally for the life of the unit means no maintenance is required, saving labor time, and promoting cost reduction over the span of the electric actuator’s service life.

Options for waterproof Ingress Protection and salt spray ratings for more corrosion resistance further improve lifespan which reduces the need for frequent replacements. Electric actuators also ensure an environmentally friendly means of providing linear motion without any risk of oil leaks thanks to fewer working components and simpler operations compared to hydraulics and pneumatics.

As one of the top suppliers of electric linear actuators, Progressive Automations offers industry-leading flexibility, quality, support, and field experience to meet all your needs. If you have any other questions about what we can offer, please do not hesitate to reach out to us! We are experts in what we do and want to ensure you find the best solutions for your application.

sales@progressiveautomations.com | 1-800-676-6123